BACKED BY SCIENCE

TriboTEX is a revolutionary breakthrough in engine coating technology. Conceptually, the technology is straight forward. The material science, however, is quite sophisticated. Engineered, synthetic nanoparticles are designed to be grippy on one side and slippery on the other. When added to engine oil, these nanoparticles attach to metal surfaces (grippy side down), one by one, exposing the slippery side to reduce friction.

After 500 miles of normal driving, internal components are coated with a porous, lubricious tribofilm exhibiting excellent embeddability and oil retention. The slippery surface contains select catalysts, incorporated by design, facilitating the formation of a Diamond-Like Carbon (DLC) cap on top.

Originally these self assembling coatings were developed for improving performance of gearboxes under the grueling demands of wind turbines. The TriboTEX platform was constructed with over $1 million in research and development support from NASA, NSF, DOE, and the U.S. Air Force.

To learn more about the science behind TriboTEX and see the results for yourself, download our reports below.

From the FAQs

TriboTEX nanoparticles have two sides, one that binds and one that glides. The grippy side reinforces and strengthens, while the slippery side reduces friction.

Just like carbon in the mantle of the earth, they self-align into a diamond-like armor under the heat and pressure of your engine, grippy side facing in and slippery side facing out. This coating dramatically reduces friction, down to superlubricity levels.

See more Frequently Asked Questions

Scientific Reports

TriboTEX is a research company at heart.

All our products are backed by rigorous testing and accepted standards set out by ASTM and the API. Unlike most oil additive companies, we’re willing to show you the data behind our products. We know it works. And we want you to have the confidence to know it works too.

From racing enthusiasts to corporate fleets owners, the technical merits show it’s up to the challenge. We are currently pursuing additional double-blind, independent testing. This is being done verify our claims and meet our customers’ requests. If you have additional testing you’d like us to provide, schedule a consultation today!

Material Safety Data Sheet (MSDS)

TriboTEX is safe for the environment and your car. Read our Safety Data Sheet for absolute peace of mind.

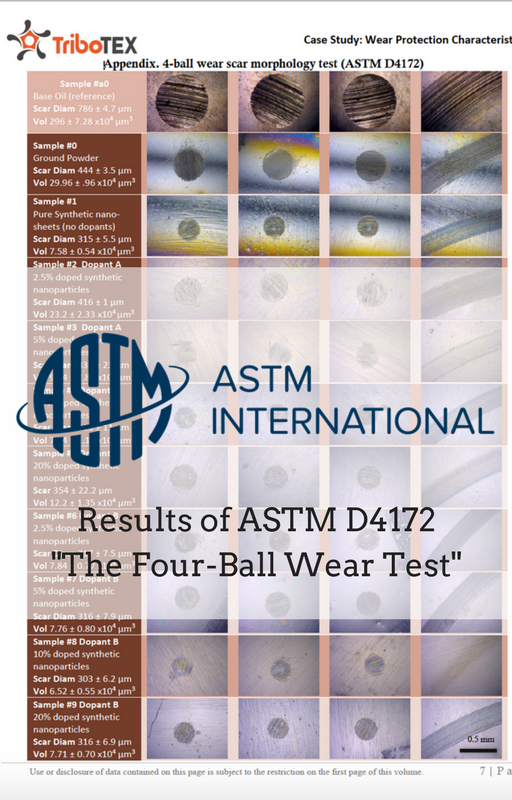

The Four-Ball Wear Test: The #1 Predictor of Wear Resistance

Scientists at ASTM International agree that one of the best predictors of wear protection is the Four-Ball Wear Test. This test uses four ½ inch ball bearings coated in a lubricant and rotated under high pressure. One of the bearings rotated at a high speed (1200 RPM) while pressed against the other three. This leaves scars on all four balls.

The results are simple to measure. The better the lubricant is at preventing wear, the smaller the scars. TriboTEX has been tested to show 40X less wear than synthetic oils alone. This is the #1 reason old car owners love TriboTEX. Less wear on your engine's hardest working parts means it can last a longer.

Want to see all the pictures of the worn ball bearings for yourself?

Enter your name and email below to see the report.

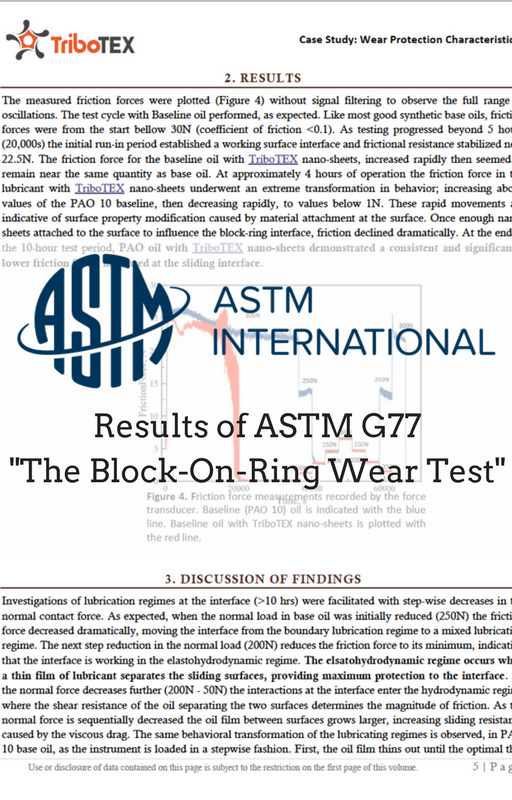

The Block on Ring Test: The “Gold Standard” for Lubrication

Tribologists (read: friction geeks) use the Block-on-Ring Test to measure good ‘ol metal-on-metal contact friction. It’s that same type of friction that can weld your pistons right to the bore walls without motor oil. The active nanomaterial in TriboTEX was first discovered using this test.

The most important result of this test showing the power of TriboTEX is the sharp drop you’ll see in the measured friction force. This is after TriboTEX has bonded to the surface. Compared to traditional polyalphaolefin (PAO) oils found in synthetic motor oils, oil treated with TriboTEX reduced friction by 10X when under similar pressures found in your engine.

That’s one stat that will make your engine hum in with satisfaction.

Just enter your name and email below to see it all for yourself.

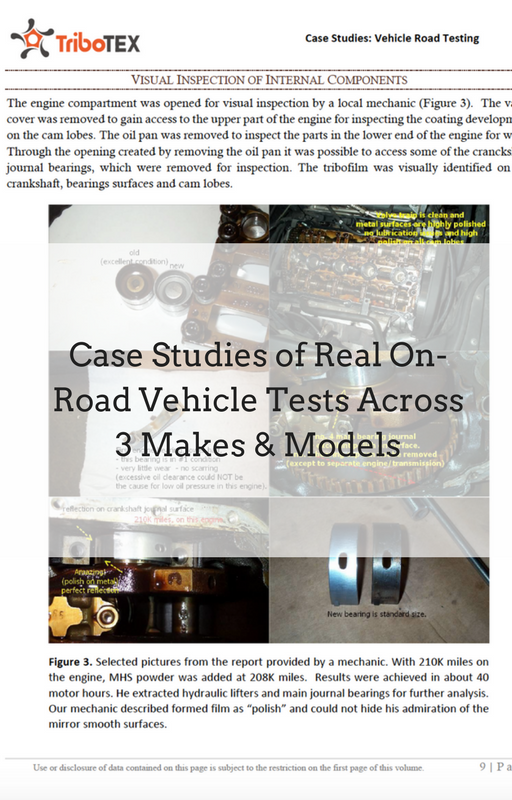

Live On-Road Test Results With TriboTEX

If you could only read one report, this would be it. This gives all our hard data behind TriboTEX in the real world. We started live road testing on company vehicles once we saw TriboTEX’s lab results. Friends of the company were also lining up to test this on their own vehicles.

We documented all the performance changes across three different test vehicles:

- 1999 Volskwagen Passat, 1.8 AEB Turbocharged

- 2015 Ford Mustang, 3.7 L V6 Turbocharged

- Two (2) 1st Generation Priuses, 1.5 L Atkinson Cycle Engine and Toyota Hybrid System

The results exceeded our wildest expectations:

- The Passat showed a 5-6% increase in MPGs even with 208K miles under the hood.

- The 2015 Ford Mustang showed a 3.1% increase in horsepower on the dynamometer.

- The test Prius got 4% better gas mileage on two different mountainous road courses.

Enter your name and email address to see the full report.

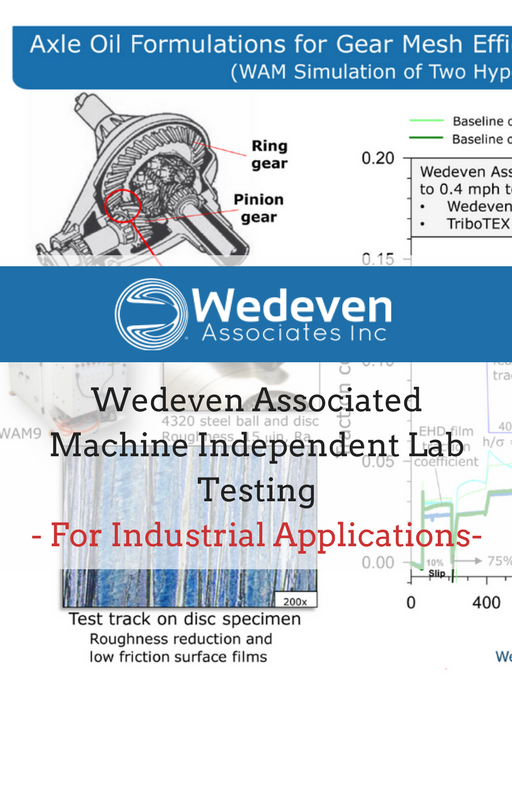

Industrial Gearbox Testing With TriboTEX

Few people outside of the world of tribology know about Wedeven Associated Machine (WAM). But if a Big Three car company needs test data on a new gearbox, WAM is the first place they go. Wedeven has been around for over three decades and was founded by Dr. Lavern D. Wedeven.

While Dr. Wedeven isn’t teaching graduate tribology classes at MIT, he serves as WAM’s president. He’s published over 90 technical publications, worked with NASA, and holds two patents in lubrication and tribology test equipment. Dr. Wedeven knows lubrication science better than mechanics know their favorite tool chest.

They’ve also done independent testing for TriboTEX to see the industrial potential of our nanomaterial. In their setup used to test fluids for big-rig truck differentials, they found an 11% reduction in the “traction coefficient.” This means the gears more easily slide past one another, cutting down on wear and tear.

Enter your name and email below to see the report.

The Hard Science Behind TriboTEX's Effectiveness

TriboTEX’s company roots are firmly in the R&D of engineered nanomaterials. Even as we sell direct to drivers all over the world, we’re pushing the boundaries of research. This report published in Feb 2017 explains the PhD science behind why TriboTEX works. It talks all about our diamond-like coating and how it sticks to metal.

We’d normally offer this report to you free of charge with our other documents, but legally we can’t. Tribology International owns the rights to distributing the report and all images associated. If you have a thirst for “why” TriboTEx works, you can buy the report here from Tribology International:

Don't want to pay for the report? Check with your local library to see if they have a subscription to Tribology International. You can enter your zip code here to find a library nearby: